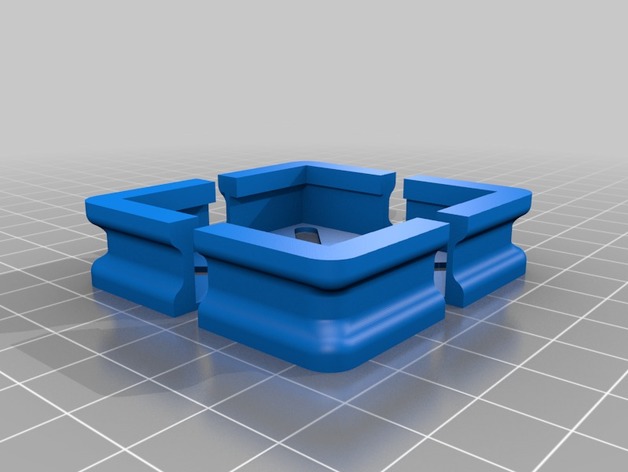

Download Free 3D Model Glass Plate Corner Brackets for Flashforge Inventor 3D Printer (Remix) 3D Print Model

Summary

These corner brackets were designed to interface with the Flashforge Inventor 3D printer and the glass plate upgrade from Flashforge USA. Supports glass dimension (L x W x H) 9 x 6 x 0.15 inches. Glass must be installed on top of the Flashforge build tape and aluminum build plate. You may require four washers to prevent the hex nuts from going through the gaps of the corner brackets.

The corner brackets are designed to be of sufficiently low profile to accommodate the build plate movements in proximity of the internal filament spools. The corner brackets can be fastened using the existing build plate hardware and are flush with the surface of the glass.

I would like to say that this project worked on the first attempt but it would be false. What started as a deliberate design attempt turned into a series of trial and error. It took me seven versions to get it right.

Print Settings

Printer:

Flashforge Inventor

Rafts:

No

Supports:

Yes

Resolution:

0.08mm

Infill:

100%

Notes:

In order for these brackets to work at bed temperatures up to 110 degrees Celsius, I recommend using Proto-Pasta Carbon Fiber HTPLA for printing these and then following directions from Proto-Pasta for annealing. I do not recommend the use of regular PLA or ABS for this project as they will become soft and rubbery during heated bed operation.

To ensure compatibility with your system, here are the measured dimensions of the parts that the brackets interface to:

Original Aluminum + PCB + Tape Build Plate (L x W x H) 232 x 153 x 8.25mm

Glass Plate Upgrade (L x W x H) 229 x 152.45 x 3.8mm

I recommend tightening the nuts once the build plate is fully raised and pre-heated to 60-70 degrees Celsius.

How I Designed This

Step 1: New Enhancements

After having used the source version of these for two months, I discovered some areas for improvement. I increased the height of the opening that interfaces with the “Original Aluminum + PCB + Tape Build Plate” by 0.2mm in order to get an even better fit. I also reinforced the external sides of the corner brackets as they seemed to start warping slightly at 110 degrees Celsius (even with the annealed Proto-Pasta Carbon Fiber HTPLA). I think that with the thicker material, which is an insulator, the part should maintain its shape. This is still a work in progress in that I have not yet printed it to verify the fit and conduct some testing; I plan on having it verified and tested next week.

Categories: 3D Print Models, All 3D Models, Free 3D Models

Sorry, comments are closed for this item.