Download Free 3D Model Gear set for cutting 10 pitch on a Hardinge TL 3D Print Model

Summary

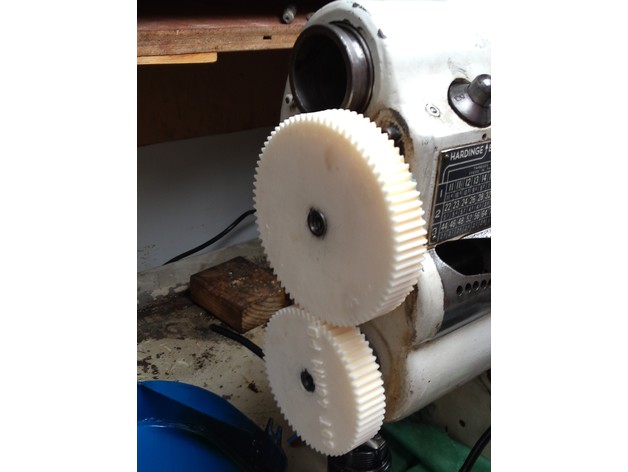

To start, I measured the center to center on the two shafts on my Hardinge TL lathe that are used for external gearing. After some math I worked out that the ratio I needed was 25:16, with the big gear on the top. Knowing that I simply made two gears with a totally random pitch that had the right pitch circles to get the ratio right (48mm pitch diameter on the small one). FYI, going to 150 teeth on the big one gets the teeth too small for reliable printing. The set I actually built is 75 tooth by 60 tooth; sorry about the file name!

In use, you have to remove the external gear cover AND shift into the external gearing mode (all the way right on the quick change) AND set the three change to “1”.

These gears are a bit scary to use; stay the heck away from then while running! A little way oil (sticky) is a good idea. I was able to cut the 10 pitch Aluminum thread I needed using these without any visible damage on the teeth or bore.

Print Settings

Printer:

WeldingRodBot

Rafts:

No

Supports:

No

Infill:

50%+

Notes:

Its been a long time since I printed these, so I’m not totally sure what I did. I would use at least 3-4 shells with a 0.4mm nozzle.

You will need to ream out the bore and clean the keyway with a needle file. The bottom edges of the teeth are likely to need cleaning too, though you might be able to run one with the build surface toward the lathe and the other away from the lathe and get away with minimal finishing.

Categories: 3D Print Models, All 3D Models, Free 3D Models

Sorry, comments are closed for this item.