Download Free 3D Model MPSM Fully Adjustable Z Spacer (MP Select Mini) 3D Print Model

Summary

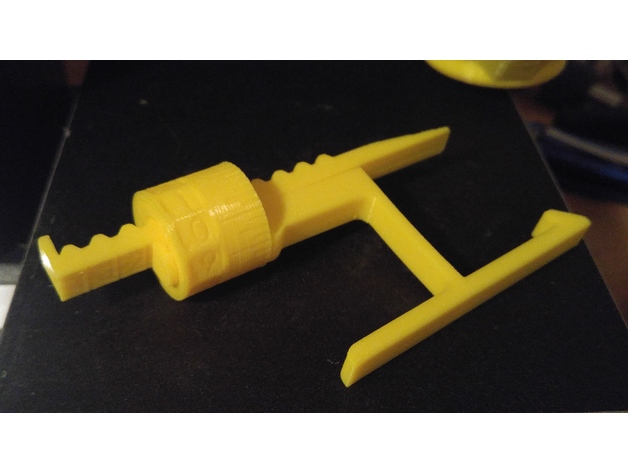

Fully Adjustable Z Spacer

MP Select Mini

By Wiley Kyoto

This Z spacer is designed to give you continuous adjustment from 1mm to 5mm. If you want to switch between the stock bed and glass bed, you don’t have to adjust your print bed and then re-level it. If the beds already level, just adjust the spacer for the change in height to account for the glass thickness. Also If you change nozzles, the new one might be slightly longer or shorter, so just adjust the Z offset accordingly. I gave the Bracket a slight bend so it keeps constant pressure to hold it firmly in place.

My Print Setup:

PLA

210/60C

No Supports

0.175mm Layer Height

1.4mm Wall Thickness

1.05mm Top and Bottom Thickness

Orientation – Lay the AdjArm and Bracket flat on their sides. Put the AdjDial on one of the flat ends (I had numbers near the top).

Assembly:

Put the AdjDial on the Bracket, in the groove next to the indicator mark, with the numbers closest to the outside edge.

Insert the sloped edge of the AdjArm through the AdjDial, with the threads of the AdjArm facing away from the Bracket.

Keep pressure pushing the AdjArm into the AdjDial as you start to turn the AdjDial clockwise. Keeping in mind that the thread is reversed thread, such that turning the AdjDial clockwise will wind the AdjArm farther in.

Set the AdjDial to roughly the right spot (See Reading the Dial).

Make sure the head position of the printer is a good couple centimetres in the +Z direction, to prevent damage to the Z limit switch.

Insert the assembled spacer through the vertical slot in the back of the printer tower, snapping it into place on the Z Bearing Block(Black Plastic Block with metal rods running vertically through it), which you can see through the vertical slot. You should hear and feel a solid click as it snaps securely into place, pushing forward firmly on the top lever of the spacer should help it snap into place.

Make final adjustments the the AdjDial but homing the printer and checking the fit with a piece of paper under the nozzle.

Reading the Dial:

Note – the readings won’t have absolute accuracy as it depends on the exact placement of the Z Limit switch, but the relative accuracy should be great.

The AdjArm has 4 notches, with numbers 1 to 4 next to them. These represent whole mm steps.

The AdjDial has 40 notches, every 4 notches are numbered .0 through .9. These represent decimal mm steps. Each notch is a 0.025mm step.

The Bracket has one indicator notch which lines up with the notches on the AdjDial to indicate where to read the setting.

When the outside edge of the Bracket is lined up with the first notch(next to the 1) on the AdjArm and the .0 setting on the AdjDial is centred on the indicator notch, the spacer is set to 1.0mm.

When the AdjArm is all the way into the AdjDial, and the AdjDial is set to .0, the spacer is set to 5.0mm.

The spacer can be set less than 1mm but at some point (around 0.7mm on my printer) the limit switch will slip off the end of the spacer and effectively act as 0mm offset.

Categories: 3D Print Models, All 3D Models, Free 3D Models

Sorry, comments are closed for this item.